|

I first started out by trying to use the lift to raise the head off the block against the engine's own weight. That didn't work....

|

|

I resorted to a big hammer and a block of wood - seen in the background. Eventually it came off, but after

|

|

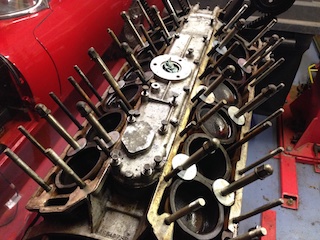

....and an end-on view.

|

|

Other than a high degree of carbon, the engine looks largely OK. I think I got lucky as only one or two studs each side were dragging and you may be able to see white residue on some of the studs. The ones at the ends that do not run in the water jacket look like new. I think I am lucky in that the Jaguar service schedule involving Bars Leak was probably not followed too enthusiastically. Once the seal was broken, I could feel the heads rocking on the one or two studs that caused the sticking and a bit of persuasion with a hammer did the rest.

|

|

The final job, for now, was to ensure the liners were fixed in position so the engine can be turned over without them moving. This was done with large washers and round tube.

|